VIsite

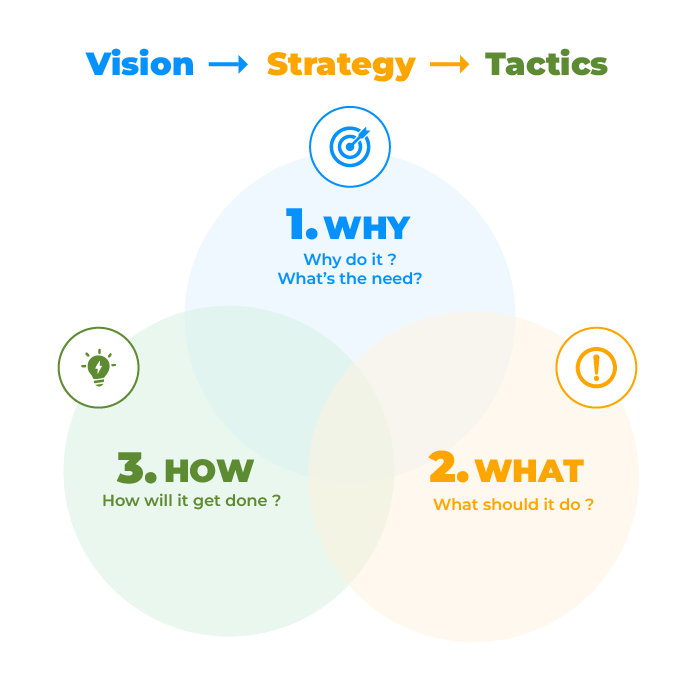

Agile approach

To meet the challenges of efficiency and agility,

Ekium is committed to continuous improvement.

Agility makes it possible to secure the project, increase responsiveness, and continuously adapt to changing needs.

OVERALL VISION : AUDITING – ENGINEERING – CONSULTING

Strategic Support

Our digital expertise is based on the industrial DNA of our teams, combining technical expertise and understanding of sectoral issues.

We offer a comprehensive approach, including the integration of market solutions, as well as our own platform developed in-house, tailored to your specific needs.

Our strengths are :

-

-

- Technical expertise

- Multi-trade experience

- Pragmatic solutions proposed

-

-

-

- Functional

- Technical

- Economic

-

-

-

-

DESIGN

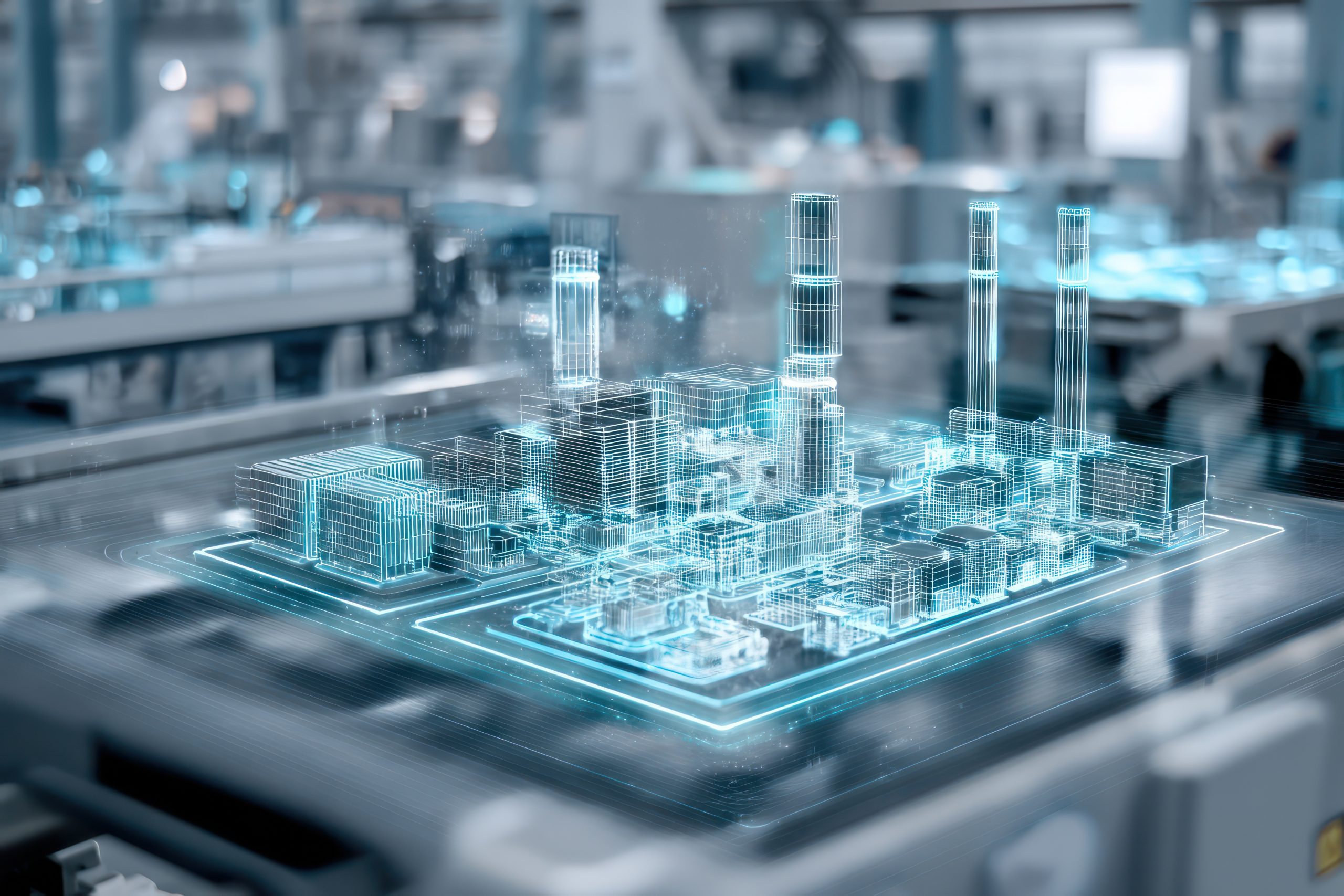

Digital twin

Simulate, test, and validate a process :

-

- Virtual unit 100% faithful in the actual process

- We test errors, cycles, settings

- Ability to test multiple scenarios without impacting production

- Enables training of new operators

-

- Change management

- Learning complex scenarios

-

DESIGN + AUTOMATED LOADING

Modular workshop configuration

Prepare and test without risk :

- Modular and scalable production : make each scenario reliable

- Simple graphic interface simple to create

-

- a configuration (PID)

- a product recipe

-

- Off line preparation

- Loading for online execution

- No Code + no user manual

PLANNING

Anticipate conflicts

- Intuitive interface to plan the WO (Working Order)

- Management of available resources

- Business conflict management or capacity

- No training required

Flexible production

Batch Manager

Text under maintenance

Digitization from A to Z

Business process management

Customer activity

Manufacture of hard capsules for pharmaceutical applications

Current status :

-

Manual, paper-based process

-

Partial and unreliable traceability

-

Data not centralized or analyzed

-

Significant risk of human error

Objective :

- Digitization of the process from start to finish

- History of operator actions

- Accurate tracking of operations

- Alerts in case of deviations or anomalies

- Data that can be used directly

Simplifies the daily lives of operators and managers

No Code Solution

Immediate start :

- Like any consumer application

- Access from phone, tablet, or PC

Improves your processes :

- 100% No Code Configuration

- Simple and user-friendly interface

Maintain

Coactivity management

Subject

Digitizing the management of factory shutdowns.

Current status :

- Manual tracking (Excel, paper), therefore errors

- Non-centralized information, slow updates

- Too much equipment to manage

- Wasted time in the field

- Limited visibility for the planner

Objective :

- Provide a simplified planning tool

- Track progress in real time

- Rapid alerts and notifications for operators

- Access to a comprehensive overview with risk zone detection

- Enable testable scenarios to assess impacts

DATA

Leverage your data

Collect :

- OT & IT sources

Prepare :

- contextualize the data

- Perform pre-treatment

Store – Restore :

- Industrial Solutions

- IT solutions – web technology

Securise

Cybersecurity

Text under maintenance

Contact details

Phone

06 70 64 08 21

omer.akdeniz@ekium.eu

Adress

5 Rue abraham bloch, 69007 lyon